As electric vehicles (EVs) and renewable energy storage systems rapidly expand, the need for more efficient battery recycling processes has become critical. With the global shift toward reducing carbon emissions and increasing reliance on sustainable energy sources, lithium-ion batteries have become the backbone of modern EVs and energy storage systems. However, as demand grows, so does the challenge of managing used and end-of-life batteries in an environmentally responsible way.

The Importance of Battery Recycling

Battery recycling is essential for several reasons. First, it mitigates the environmental impact of battery waste, which contains harmful chemicals and metals that can be toxic to ecosystems and human health if not properly handled. Second, recycling conserves valuable raw materials such as lithium, cobalt, nickel, and manganese, which are integral to battery manufacturing but are limited in supply and often require environmentally damaging mining processes.

Recycling also helps stabilize supply chains for critical battery materials, reducing dependency on geopolitically sensitive regions and lowering the costs associated with sourcing raw materials. As EV and energy storage adoption grows, improving battery recycling processes becomes crucial to creating a sustainable circular economy for these technologies.

Current Battery Recycling Processes

Battery recycling is still in its early stages, with most processes focusing on recovering key metals through mechanical and chemical methods. The two most common approaches are:

- Pyrometallurgy: This method involves smelting batteries at high temperatures to extract valuable metals like cobalt, nickel, and copper. While it is effective at recovering certain materials, it is energy-intensive and not particularly efficient at recovering lithium, a critical component of modern batteries.

- Hydrometallurgy: A more advanced technique that uses chemical leaching to dissolve metals from batteries, allowing for the separation and recovery of individual components. This process is more energy-efficient and better at recovering a wider range of metals, including lithium, making it a promising solution for the future.

However, both methods face challenges, including the high cost of operations and the complexity of safely handling used batteries, especially when they retain significant charge.

Innovations in Battery Recycling

As the need for better battery recycling processes grows, research and development efforts are ramping up to find more sustainable and cost-effective solutions. Some promising advancements include:

- Direct Recycling: Unlike pyrometallurgy and hydrometallurgy, direct recycling focuses on preserving the battery’s structure and components instead of breaking them down into raw materials. This method allows for the recovery and reuse of battery cathodes, which can significantly reduce the need for new materials and energy. Direct recycling is still in its experimental phase but shows promise for future scalability.

- Second-life Applications: Many EV and energy storage batteries still have a significant capacity after their primary use. Instead of recycling them immediately, these batteries can be repurposed for secondary applications, such as grid energy storage or backup power systems. This approach not only extends the lifespan of the batteries but also reduces waste.

- Enhanced Material Recovery: Researchers are exploring more efficient chemical processes that can increase the recovery rate of valuable materials like lithium. New technologies in hydrometallurgy are being developed to improve selectivity, energy efficiency, and scalability, making it easier to recover a higher percentage of critical metals.

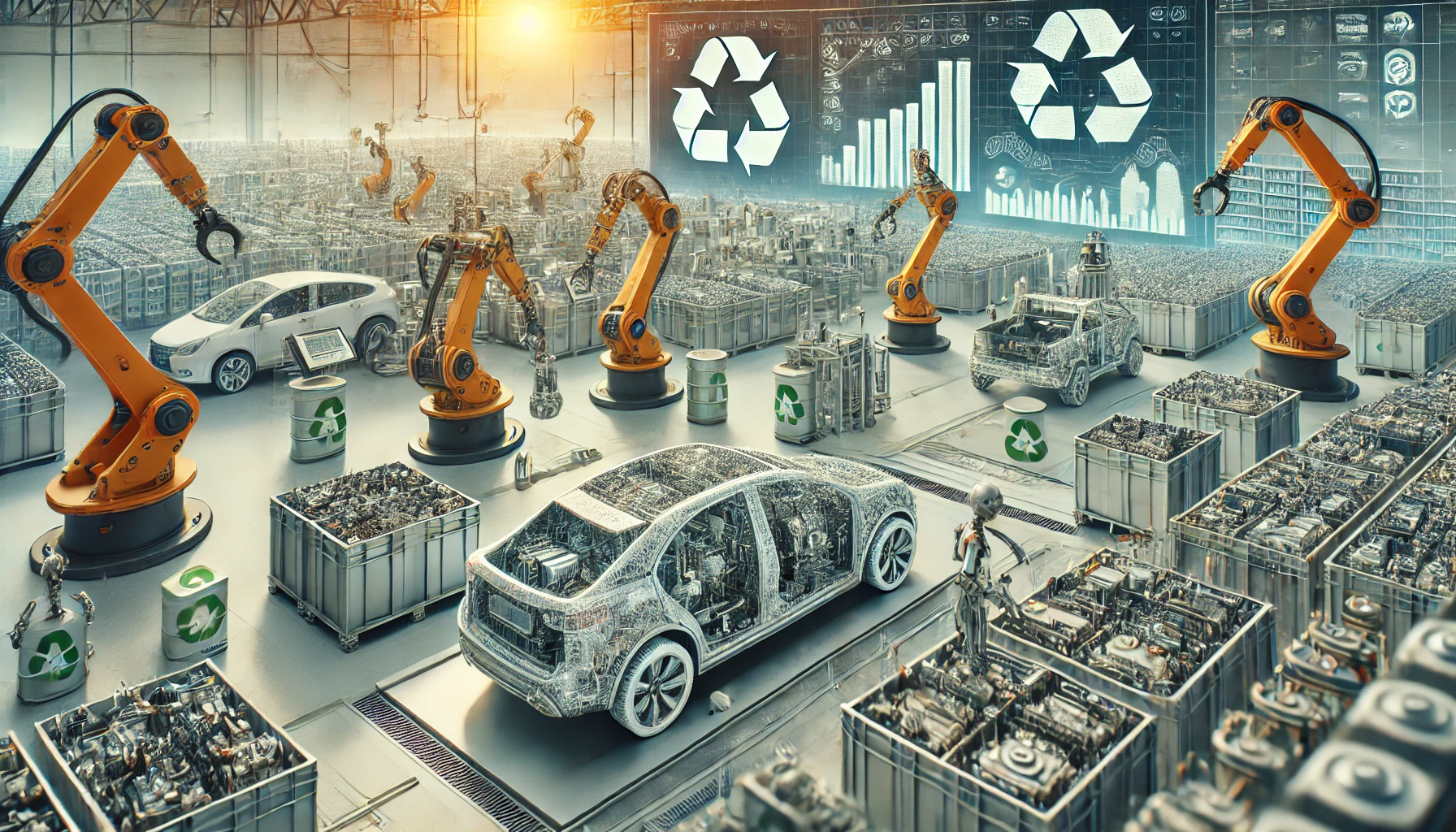

- Automated Battery Dismantling: Automation is playing a growing role in battery recycling, with new systems designed to safely disassemble batteries and separate materials for recovery. These systems can reduce labor costs and increase efficiency, while also minimizing the safety risks involved with handling used batteries.

The Role of Policy and Investment

Governments and industries are recognizing the importance of battery recycling as a key component of sustainable energy strategies. In the European Union, regulations are being introduced to set mandatory recycling quotas for EV batteries, ensuring that a minimum percentage of materials are recovered and reused. Meanwhile, major automakers and battery manufacturers are investing in recycling infrastructure and partnerships to support the development of a circular economy.

Private investment is also flowing into battery recycling startups, with companies focusing on next-generation technologies that can process batteries more efficiently and at lower costs. For instance, J.P. Morgan and other financial institutions are supporting research and innovation in this field, recognizing that improved battery recycling is crucial for long-term sustainability in the EV and energy storage markets.

As the world transitions to electric mobility and renewable energy, battery recycling will play a pivotal role in ensuring that these technologies remain sustainable. With advancements in recycling processes and increasing investments in research and infrastructure, the future of battery recycling looks promising. By embracing these innovations, we can reduce the environmental impact of battery waste, conserve valuable resources, and pave the way for a greener future.

Sources:

- J.P. Morgan | Official Website

- European Battery Alliance Initiative

This ongoing research into improving battery recycling processes is key to supporting the expansion of EVs and energy storage systems, ensuring a sustainable and circular economy for years to come.